In today’s manufacturing landscape, companies are looking for ways to digitize their production and to improve their processes and products. At the same time, implementing digitalization solutions can be a cost- and resource-intensive process, particularly for smaller companies. The EU project Change2Twin* was started two years ago with the goal of supporting small and medium sized enterprises (SMEs) in their digitalization journey. Aside from supporting the companies themselves, it also gives a platform to technology providers for testing out their solutions in pilot projects for different digital twin use cases.

As defined by Change2Twin, their aim is to help create digital twins that replicate a product, manufacturing process or service so accurately that its performance can be predicted and used as a basis for decision-making.

Dr. Francesca Flamigni, Innovation Projects and Funding Manager at TTTech explains: “There is not one standard digital twin solution for everyone. That is why the Change2Twin project has several deliverables. Firstly, we test technology for digital twins in pilot projects and publish our learnings in a catalogue of technologies for companies to choose the best solutions for their own business case. Secondly, the technology providers can expand their knowledge of digital twin and adapt their solutions better for this use case. Thirdly, we provide funding and guidance to SMEs selected in our open calls in 2020 and 2021 to help them conceptualize and implement their digital twins. This supports the digitalization and thus the competitiveness of the European manufacturing sector.”

In a virtual kick-off event in March 2022, the Change2Twin consortium, technology partners and SMEs selected in the open calls discussed the conditions of the upcoming 11-month deployment program and started the digital twin implementation rounds. TTTech Industrial is a consortium partner in the Change2Twin project and contributes by providing its edge computing platform Nerve as one of the technologies enabling digital twins.

Supplying secure, real-time data for digital twins

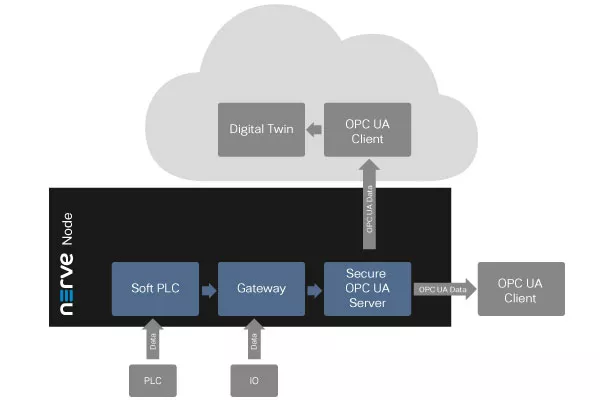

Nerve is an open, modular solution that allows users to integrate devices from different vendors, so they have a maximum of choice. Aside from the base system that provides a secure foundation for managing software and devices, customers can choose from four modules combining different feature sets. These can be licensed individually or in combination, so customers can start small and later add more functionalities as best fits their business needs and budget.

“Nerve is a solution that connects IT with operational technology (OT) on the shopfloor and grows with the customers’ business. When it comes to digital twin, customers might first want to start with just collecting data, but as companies scale up and own hundreds of machines all over the world, they may need to centrally manage all their devices and to deploy applications remotely,” explains Elisabeth Meisel, Manager Sales Industrial IoT at TTTech Industrial.

Data is key as a basis for digital twins and for their connection to the physical world (i.e. the object and processes they represent). Nerve enables secure access to the machine data that is used as the base of the digital twin.

With Nerve’s Data Services module, customers can ingest data from a host of different sensors or connect to a Siemens PLC, process data at the edge, store it, or visualize it in a database on the node or in the cloud. Data Services also offers the option to create edge analytics. All of this is possible both in online mode and offline, thanks to data buffering, ensuring that no data is lost. For access to fieldbus-level sensors and actuators, customer can use the Soft PLC module, which can also be used to run machine control workloads on standard industrial hardware.

Pilot project – digital twin with Nerve for the packaging industry

TTTech Industrial worked with packaging producer Robopac in one of the four Change2Twin pilot projects. Robopac wants to use the digital twin for the optimization of pallet load packaging to ensure stability and security, as well as reduce the amount of plastic packaging needed. In this case, the digital twin is a virtual model of the pallet load, created with assistance from the University of Bologna.

The physical behavior of the pallets during transport is analyzed experimentally, using a motion platform and other testing machines. The model is then used to calculate the amount of packaging materials needed and which material is best suited to the selected transport route. Users will be able to graphically depict the packaging cycle for the packaging machine and reduce the use of plastic film. Nerve is used in the pilot to collect and analyze data at the edge close to the end user, thus ensuring security and privacy of data. The 2D model will be run on Nerve as a virtual machine. The Nerve Management System will enable customers to update new packaging materials or products.

Elisabeth Meisel adds: “The Robopac project is a good example of what Nerve can bring to digital twins. With Nerve, customers can gain secure access to real-time machine data, unify and analyze it, and we can also help them to extend the digitalization of their production with remote device and software management. We cover a wide range of use cases in different industries, from manufacturing to process industries, energy storage and food processing and are at home with industrial IoT standards and requirements.”

* Change2Twin has received funding from the European Union’s Horizon 2020 Research and Innovation program under grant agreement No 951956.

Find out more:

- Discover Nerve’s four modules and their features

- Start now with a free trial of Nerve

- Read more about how our customers use Nerve in our case studies and whitepapers

- Check out our online demo with Microsoft, where we showed the implementation of a digital twin example (Asset Administration Shell) as part of a virtual Nerve Robot Demo

- Details on the Change2Twin project at TTTech Group’s website

- Change2Twin website

- Nerve on the Change2Twin marketplace

- Whitepaper: Nine digital twin barriers for manufacturing SMEs – and why they are worth tackling